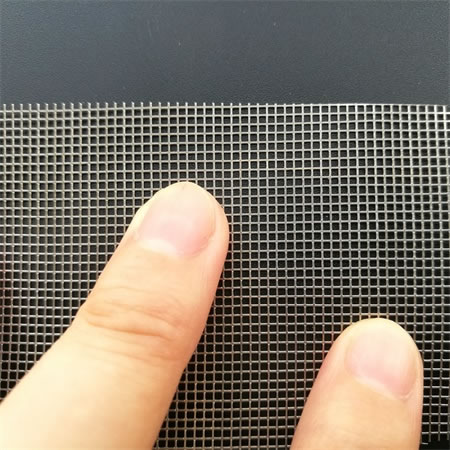

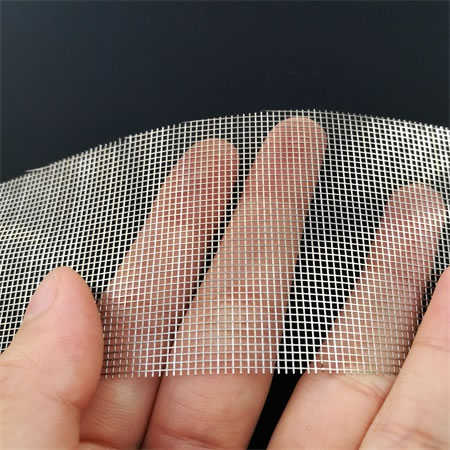

Nickel 200 wire mesh is commercially pure and has good mechanical properties and excellent corrosion resistance to alkalis i.e. Sodium hydroxide. Nickel 200 mesh also has good electrical, thermal and magneto-strictive properties, like it is well-suited to over 600°F operating temperature.

Physical testing department and quality control department is available, operating an all-round monitoring from raw materials to final products.

This kind of rolled Nickel wire mesh can be applied into batteries.

The wire diameter, mesh count and aperture can be customized, as well as the mesh dimensions.

Specifications:

Mesh count: 0.5 - 250 mesh

Wire diameter: ≧ 0.04mm

Thickness: ≧ 0.08mm

Roll size: 0.914m x 30m, 1m × 30m; 1.22m×30m

| Approximate Chemical Composition % | |||||||

| Ni | C | Mn | Cu | S | Si | Fe | |

|---|---|---|---|---|---|---|---|

| Max. | 0.15 | 0.35 | 0.25 | 0.01 | 0.35 | 0.40 | |

| Min. | 99.0 | ||||||

Characteristics:

Highly resistant to various chemicals and distilled & natural water

Excellent resistance to caustic alkalies & neutral and alkaline salt solutions

Excellent resistance to dry fluorine and hydrochloric and sulfuric acids at modest temperatures and concentrations.

Good thermal, electrical and magnetostrictive properties

| Properties | ||

| Density | 8.89 g/cm3 | 0.321 lb/in3 |

|---|---|---|

| Melting Point | 1446 ℃ | 2635℉ |

| Coefficient of Expansion | 13.3 μm/m℃ (20 - 100℃) | 7.4 × 10-6 in/in℉ (70 - 212℉) |

| Modulus of Rigidity | 81 kN/mm2 | 11748ksi |

| Modulus of Elasticity | 204 kN/mm2 | 29588ksi |

| Electrical Resistivity | Thermal Conductivity | ||

|---|---|---|---|

| 9.6μΩ • cm | 58 ohm • circ mil/ft | 70.2 W/m • ℃ | 487 btu • in/ft2 • h •℉ |

| Condition | Approx Tensile Strength | Approx Service Temperature | |

|---|---|---|---|

| Annealed | 400 - 500 N/mm2 | 58 - 73 ksi | Tensile strength and elongation drop significantly at temperatures above. |

| Hard Drawn | 700 - 900 N/mm2 | 315°C (600°F). Service temperature is dependent on environment, load and size range. | |

Applications:

Food Processing

Synthetic Fiber Processing

Heat Exchangers

Chemical Industries

Electrical Industries

super duplex wire mesh, hastelloy-B wire mesh, hastelloy c-276 wire mesh, hastelloy X wire mesh, inconel

600 wire mesh, inconel 601 wire mesh, inconel 625 wire mesh, inconel 718 wire mesh, incoloy 800 mesh, kanthal D

wire cloth, alloy L605 wire mesh, molybdenum (moly) wire cloth, monel-400 wire mesh, nichrome wire cloth, nickel

wire cloth, silver wire cloth, tantalum standard grade wire cloth, titanium wire cloth, tungsten wire cloth, hardware

cloth, stainless steel wire mesh, aluminum wire cloth, brass wire cloth, bronze wire cloth, copper wire cloth,

super duplex wire mesh, hastelloy-B wire mesh, hastelloy c-276 wire mesh, hastelloy X wire mesh, inconel

600 wire mesh, inconel 601 wire mesh, inconel 625 wire mesh, inconel 718 wire mesh, incoloy 800 mesh, kanthal D

wire cloth, alloy L605 wire mesh, molybdenum (moly) wire cloth, monel-400 wire mesh, nichrome wire cloth, nickel

wire cloth, silver wire cloth, tantalum standard grade wire cloth, titanium wire cloth, tungsten wire cloth, hardware

cloth, stainless steel wire mesh, aluminum wire cloth, brass wire cloth, bronze wire cloth, copper wire cloth,

super duplex wire mesh, hastelloy-B wire mesh, hastelloy c-276 wire mesh, hastelloy X wire mesh, inconel

600 wire mesh, inconel 601 wire mesh, inconel 625 wire mesh, inconel 718 wire mesh, incoloy 800 mesh, kanthal D

wire cloth, alloy L605 wire mesh, molybdenum (moly) wire cloth, monel-400 wire mesh, nichrome wire cloth, nickel

wire cloth, silver wire cloth, tantalum standard grade wire cloth, titanium wire cloth, tungsten wire cloth, hardware

cloth, stainless steel wire mesh, aluminum wire cloth, brass wire cloth, bronze wire cloth, copper wire cloth,